Wednesday, October 28, 2020

Tuesday, October 27, 2020

Thursday, October 22, 2020

Wednesday, October 21, 2020

Elon Musk Discusses Droids and Teleoperated robots on Mars.

Monday, October 19, 2020

Fwd: [HBRobotics] Arduino has Some New Stuff.

HM01B0 Ultra Low Power CIS

320 x 320  1/11″

1/11″  Parallel & Serial Interface

Parallel & Serial Interface

The HM01B0 is an ultra low power CMOS Image Sensor that enables the integration of an “Always On” camera for computer vision applications such as gestures, intelligent ambient light and proximity sensing, tracking and object identification. The unique architecture of the sensor allows the sensor to consume very low power of <2mW at QVGA 30FPS.

The HM01B0 contains 320 x 320 pixel resolution and supports a 320 x 240 window mode which can be readout at a maximum frame rate of 60FPS, and a 2×2 monochrome binning mode with a maximum frame rate of 120FPS. The video data is transferred over a configurable 1 bit, 4bit or 8bit interface with support for frame and line synchronization. The sensor integrates black level calibration circuit, automatic exposure and gain control loop, self-oscillator and motion detection circuit with interrupt output to reduce host computation and commands to the sensor to optimize the system power consumption.

From: camp

Subject: [HBRobotics] Arduino has Some New Stuff.

To: HomeBrew Robotics Club

Friday, October 16, 2020

From indoor to outdoor scene, can the robot chassis get through the last mile?

https://mp.weixin.qq.com/s/fxpcP49ojt4qBB2WJwL1cA Translated from Chinese

From indoor to outdoor scene, can the robot chassis get through the last mile?

Remember the robot that dug holes and planted trees in the Alashan Desert in the Robot Desert Control Project of East China Normal University?

In the endless Alashan desert no man’s land, under the scorching sun, a half-person-high robot with a large spiral drill bit, driven by photovoltaic solar energy , can drill a depth of four, The fifty-centimeter pit speeds up people's desert control process.

Not only that, based on the characteristics of outdoor sports performance, outdoor application scenarios such as park inspection and disinfection, logistics transportation, agriculture, animal husbandry and forestry, industrial intelligent manufacturing, and geological exploration have also seen more and more such UGV robots.

This is a very big progress. Robots can go from indoors to outdoors, which seems to be a short distance, but it means that robots need to face a more complex environment. Different road surfaces, slopes and complex road conditions restrict the development of outdoor robots. At the same time, robots are required to have more powerful communication capabilities, environmental adaptability and perception capabilities. The problem of the last mile has been plagued by robotics companies for a long time. Why are more and more robots now able to go outdoors?

Chassis New Market

Different from the development route of AGV and AMR in indoor industrial scenes, UGV robots can continue to develop in more outdoor-like industrial-grade applications, and continue to realize the development of more scenes, first of all thanks to the development of robot chassis. As the basic module for robots to move, the robot chassis undoubtedly plays a vital role in the extension of similar outdoor scenes. It can be said that the foundation of successful industry applications is inseparable from an excellent mobile bearer platform.

However, if companies in various industries design and develop chassis independently, they often face the problems of long cycle and high cost. Therefore, relatively common robot chassis have always existed in the market. In recent years, companies such as Canada's ClearPath have also emerged in this field. The company was once considered to be one of the largest and most well-funded startups in the service robot field.

There are also such companies in China that focus on the manufacture of robot chassis. The above-mentioned application in the Alashan Desert is the product of Songling Robot, the world's leading outdoor chassis manufacturer.

(Songling Robot Product System)

Many people in this company are no strangers to the company. Wei Jidong, the co-founder of Songling Robot, has served as DJI Innovation and R&D Manager, and is also the No. 1 employee and co-founder of Robomaster in DJI National Robot Competition. The other founding members of Songling Robot are from ROBOCON (Asia Pacific Robot Competition) and they are all senior R&D product managers.

The well-known product of Songling Robot is the all-round chassis product SCOUT, which was launched in 2018. The good off-road performance of this product can make the robot have the ability to adapt to complex environments, and because of its strong versatility and Open source, it sold out quickly after it started shipping in November 2018, and was subsequently praised by many school and laboratory users. Many schools and laboratories began to explore the outdoor work of robots with this universal chassis. The SCOUT2.0 released by the company in March this year is more because it can support the current mainstream communication modules, and has attracted widespread attention from many industry companies. Some commentators believe that Songling Robot may become ClearPath's number one competitor.

Today, Songling Robotics has once again released HUNTER 2.0, a new product of mature industrialized chassis, hoping to continue to lead the development trend of robot chassis. Where is the secret that they can continue to innovate? What innovations are worth looking forward to for new products? In this article, the Robot Lecture Hall will analyze the product parameters of HUNTER 2.0 and reveal the secrets of Songling Robot product innovation.

(Hunter2.0 vehicle)

Obvious advantages in structural design

From the products of Songling Robot, we can see that no matter from SCOUT 1.0 to 2.0, the advantages of structural design are very prominent. Its products are different from the shape of the traditional chassis. Songling Robot calls it the concept of full coverage applicable environment. And most of the reasons for its attention and praise are this.

The appearance of Songling robot products is very similar to that of automobiles. Under the newly upgraded heat dissipation and safety system, the structural design of the robot chassis has been reshaped, and the product structure also adopts a mature car-like structure. This means that the robot can improve the adaptability of the car body to the terrain while ensuring the power. For example, it can complete obstacles up to 10cm, ensure the usability of multiple outdoor scenes, and expand the indoor scene again with a more compact and compact design. , Independent suspension can adapt to various rugged paths, zero turning radius can easily control narrow environments. Based on the unique technical advantages of Songling Robot in off-road performance, Songling Robot's products continue to obtain customer orders from patrol security, construction industry, agriculture, logistics and other fields.

In the latest release of HUNTER 2.0, this new product continues Songling Robot’s consistent environmental application concept and adopts the chassis of Ackerman steering design, which makes the robot have features similar to cars. This independent front wheel steering and The swing arm suspension design allows the robot to pass through speed bumps without obstacles, while reducing tire wear, which means that the robot has the ability to work with high intensity for a long time in environments such as roads. Unlike most manufacturers' UGV robots, this design makes it suitable for working on ordinary cement and asphalt roads and has obvious advantages, which greatly expands the robot's scene development capabilities.

Power and speed coexist

The appearance design is the detail that today's technology companies pay great attention to. The HUNTER series continues the simple and generous shape of the Songling robot. The new HUNTER 2.0 adopts a steel body to make the appearance more cool.

The fuselage is equipped with a 400W dual servo motor drive. In order to ensure the movement and load capacity, each wheel uses an independent brushless servo motor and uses a swing arm suspension, which greatly improves the adaptability of the vehicle body to the terrain while achieving power. At the same time, the stability of the load and the anti-interference ability are ensured, so that the load is as high as 150KG, and the indoor and outdoor switching and unimpeded operation.

(Exploded diagram of hunter2.0 vehicle drive)

In the power system, the HUNTER 2.0 battery uses the same lithium iron phosphate solution as Tesla’s new Model 3. This new type of battery has a cheaper combination of raw materials. At the same time, HUNTER 2.0 uses a portable battery design to provide alternatives With two capacities, users can customize battery packs with different capacities according to task needs, and flexibly plug in and out switch configuration as needed.

(Removable battery for hunter2)

Like the current mainstream configuration of electric vehicles, HUNTER 2.0 also adopts a battery BMS system, which eliminates the need to use traditional wiring harnesses, saves up to 90% of the wiring harness and up to 15% of the battery pack volume, improves design flexibility and Manufacturability, without affecting the mileage and accuracy of the battery's service life, ensures that the robot is safe and worry-free during operation. It is understood that the current HUNTER 2.0 has a cruising range of up to 40KM.

Thanks to the well-designed drive system and battery configuration, HUNTER 2.0 adds a ramp parking function. This electromagnetic parking function supports the vehicle's ramp parking with power loss. By locking the tires, the robot can achieve long ramps. parking. This also means that if the vehicle is powered off or malfunctions during driving on a sloped road, the robot will not have a slope problem, which further guarantees stable and reliable work safety.

(Slope parking for hunter2)

In order to meet the application requirements of different autonomous driving scenarios and fully escort the application of industrial-grade robots, the new HUNTER 2.0 product also supports customized speed upgrades up to 10KM/H. These are personalized and unique configuration solutions similar to current electric vehicles. People can't help but think that this is a new force that makes cars.

Rapid secondary development

But different from the drive and battery details of similar vehicles, the multi-load expansion and rapid secondary development capabilities make people once again aware of the unique business logic of Songling Robot, the world's leading outdoor chassis manufacturer.

In previous reports, Wei Jidong, the founder of Songling Robotics, mentioned that unlike the traditional chassis products in the industry, Songling Robotics has clear design ideas and expansion directions from development to market positioning. Choose to focus more on other core modules and applications of the robot, hoping to help companies that have a demand for robots in a more open form to reduce the development cycle and cost of the chassis. Therefore, in the iterative process of the product, openness and ease Usability is a factor that Songling Robot attaches great importance to.

The new HUNTER2.0 product embodies this ease of use and open new features. Not only can a variety of advanced operation modes (remote driving/automatic driving) be customized on HUNTER2.0, users can also directly communicate with the master through the CAN bus protocol Communication, while providing open source SDK, ROS_PACKAGE, this structural solution is currently adapted to the most diverse automatic driving solutions.

In the previous Huawei Honor V30 conference held at the Beijing University of Technology Olympic Stadium, Song Ling Robot also joined Huawei to demonstrate the remote driving solution: SCOUT, which is far away in Shanghai, smoothly climbs and descends under the remote control of Beijing Honor V30. Turning, showing excellent off-road performance, and also reflects the high controllability and stability of the robot chassis in the 5G transmission environment for remote automatic driving.

(Use Huawei to operate the robot)

At the same time, standard profile channels are reserved around the body of the new HUNTER 2.0 product to quickly build top loads (sensing, industrial control, IMU, routing, cameras, etc.), support custom design of aluminum sensor brackets, and support more advanced automatic driving System access (such as ROS, Apollo, etc.) supports the completion of customer customization and in-depth secondary development, ensuring the robot's high flexibility and flexible operation capabilities, which also means that users only need to understand software development and basic hardware knowledge. , Given the instructions required by the equipment, it can be quickly put into application without considering the hardware development of the chassis itself. This undoubtedly saves users time, improves efficiency and reduces costs. It is widely used in inspection, detection, transportation, and teaching. Waiting scenes provide more possibilities.

(HUNTER 2.0 can support secondary development)

Regardless of the load capacity, moving speed or power of the product, it can be extended externally. It provides standardized protocols and interfaces to facilitate rapid secondary development, making this product more like a general integrated consumer product, and at the same time Being able to continuously use the open overlay function, this 1+N model may also become an important reason why Songling Robot can attract countless fans.

Conclusion

Going out of the room, going to fields, factories, tunnels, disaster sites and other harsh and harmful operating environments will inevitably become an important direction for the development of intelligent robots in the future. The majority of robot manufacturing companies and integrated companies must use this method to move from indoor industrial scenes to outdoors An all-round universal chassis improves flexibility.

For example, currently used in surveillance inspections, robots equipped with remote image transmission and capable of surmounting various slope obstacles can be used for field inspections;

In terms of logistics and transportation, the powerful maneuverability can enter narrow doors and elevators, which can be used for factory transportation where indoor and outdoor scenes are switched;

In industrial applications, industrial equipment such as robotic arms can also be assembled to complete the expansion of outdoor industrial automation scenarios;

In detection and exploration, equipped with remote remote control equipment such as image transmission, can work in dangerous and harmful environments such as tunnels, construction sites, and disaster sites;

In the agriculture, animal husbandry and forestry industries, it is equipped with sprinkler irrigation, picking, sampling, hopper and other equipment, which can also be compatible with pastures, farmland and other soil, grass and mud environments;

In teaching simulation, it has modular design and open software, and also supports autonomous driving education development and vehicle simulation scenarios.

It is foreseeable that the exploration of the commercialization path of the robot chassis + expansion service will undoubtedly be promising in the future, whether on the C side or the B side.

Finally, I attach a detailed parameter map of the new product. I hope that this good robot chassis can help more users' products get through the last mile, go out of the room, and move toward the broader blue ocean market of outdoor applications.

END

Tuesday, October 13, 2020

Sunday, October 11, 2020

Car design is about to change forever. This video encapsulates how

When you really think about it, all this is , is a robot chassis. Motors, battery power drive chain. charging,

and a small step to add a robot control layer like ROS.

https://www.fastcompany.com/90562654/car-design-is-about-to-change-forever-this-video-encapsulates-how

Friday, October 9, 2020

Thursday, October 8, 2020

Wednesday, October 7, 2020

OpenBot

OpenBot

https://github.com/intel-isl/OpenBot CODE

INTEL RESEARCHERS DEVELOP $50 3D PRINTED “OPENBOT” TO ADVANCE THE ACCESSIBILITY OF ROBOTICS

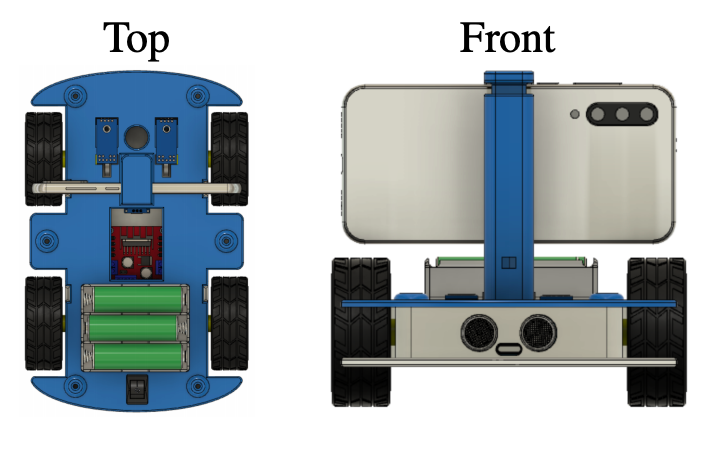

Researchers from Intel Labs have developed an open-source 3D printed smart robot that it is possible to build for less than $50.

Once combined with a modern smartphone, the additive bot is able to navigate autonomously, and its real-time sensing capabilities enable it to conduct recon tasks such as following people. The PLA-based Openbot has also been designed to be easy to build too, and its STL files have been made freely available online. By making their design public, the researchers hope that creators will tinker with and improve their robot to continue developing new applications for it in the future.

“Current robots are either expensive or make significant compromises on sensory richness, computational power, and communication capabilities,” stated the researchers in their paper. “We propose to leverage smartphones to equip robots with extensive sensor suites and access to a thriving software ecosystem, in a small electric vehicle that costs $50.”

The herculean cost of additive smart robotics

The industrial applications of smart robots have created a potentially lucrative market for businesses such as Franka Emika and Clearpath. The advanced tech firms produce highly-sophisticated legged-robots and bionic arms, but these are often well out of reach for academic institutions, costing north of $10,000 each.

Previously developed low-cost four-wheeled alternatives can broadly be sorted into three classes: tiny robots, swarm robotics and larger vehicles based on RC trucks. Swarm bots are more economical to make, but they often feature very limited sensing capabilities. By contrast, larger custom-made creations have more abundant sensors, but it has proved difficult to develop autonomous navigation for them.

“ROBOTS ARE EXPENSIVE. LEGGED ROBOTS AND INDUSTRIAL MANIPULATORS COST AS MUCH AS LUXURY CARS, AND THE CHEAPEST ROBOTS FROM FRANKA EMIKA OR CLEARPATH COST AT LEAST $10K.”

Many modern smartphones come equipped with mobile AI processors, and their ability to run complex AI models in real-time has led researchers to experiment with a smart robotic cross-over. Similar projects to that of the Intel team have previously been launched on Kickstarter, with the Botiful telepresence device and the Romo smartphone-powered drone finding success on the platform.

The Wheelphone design, which was popularized on the open-source software site Github a few years ago, probably represents the most similar layout to that developed by the Intel researchers. Unfortunately the technical limitations of the Wheelphone limited its top speed, and its high cost of around $250 caused it to be shelved, with the last update released around two years ago.

The Intel duo’s 3D printed Openbot

Inspired by projects such as Google’s Cardboard VR device, the researchers hypothesized that a smartphone could play a similar role in robotics. Using off-the-shelf parts to create a cheap physical enclosure, while allowing the mobile to act as its ‘brain,’ has plenty of benefits. In addition to being more cost-effective, the vibrant ecosystem of existing mobile apps offer the potential for numerous applications to be developed using the same hardware.

Using only an Ultimaker S5 system, the team produced the chassis, consisting of a bottom plate which is fastened to a top cover with six screws. The top plate itself features a universal smartphone mount with an adjustable spring to make it compatible with different phones, and an opening for attaching a USB-powered Arduino microcontroller.

The Openbot was programmed using a two-piece custom-designed software stack. In order to provide an interface for the operator to collect datasets and control the bot’s workload, the Intel team developed an android-based app. This was supplemented by an Arduino nano microcontroller, which controls low-level functions, and acts as a bridge between the vehicle body and the smartphone.

Taking a total of 23 hours to build, the smart robot proved capable of speeds of up to 150cm per second, making it markedly quicker than its predecessors. Aiming to assess the sensing capabilities of their Openbot, the researchers tested to see if it could follow someone independently, or even achieve autonomous navigation. Using mid-range smartphones, testing showed that the bot was able to track people at speeds of 10 fps or higher.

Although performance did prove to be device-dependent, even the cheapest phones were able to follow people for around 50 percent of the time. The researchers also trained a “driving policy” for use on smartphones, which was capable of navigating corridors and turning at intersections. Overall, the bot proved consistently able to deal with previously unseen environments, including novel objects, and dynamic obstacles such as people.

Concluding their tests to be a success, the Intel duo expressed optimism that their creation would make robotics more scalable and accessible than was previously thought possible.

“We have developed a combination of hardware and software that turns smartphones into robots,” they concluded in their paper. “We hope our work will open new opportunities for education and large-scale learning via thousands of low-cost robots deployed around the world.”

For those interested in building the Intel research team’s Openbot themselves, the files can be accessed via Github here.

Previous 3D printed smart robots

A number of other research groups have leveraged 3D printing to fabricate smart robotics, and these additive creations have taken on a vast array of shapes, sizes and functions in recent years.

In July 2020, engineering company Scheurer Swiss GmbH partnered with a group of ETH Zürich students to develop their “Rowesys” 3D printed automated robotic weeding system. The compact weed killing bot is designed to be a sustainable alternative to using herbicides in agricultural farming.

Researchers from The NYU Tandon School of Engineering and the Max Planck Institute for Intelligent Systems (MPI-IS) have built an open-source 3D printed robotic dog. The ‘Solo 8’ is designed to be low-cost and scalable, allowing those with a limited budget to construct and build an additive pet of their own.

Robotics engineers at the Georgia Institute of Technology have used 3D printed parts to create an energy-efficient ‘Slothbot.’ The robotic mammal is currently being used at the Atlanta Botanical Garden to closely monitor the animals, plants, and environment there.

The researchers’ findings are detailed in their paper titled “OpenBot: Turning Smartphones into Robots,” which was co-authored by Matthias Muller and Vladlen Koltun.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a diagram of the Intel team’s 3D printed Openbot. Image via Intel.

----

http://vladlen.info/papers/openbot.pdf

OpenBot: Turning Smartphones into Robots Matthias Muller ¨ Intel Labs Vladlen Koltun Intel Labs Abstract: Current robots are either expensive or make significant compromises on sensory richness, computational power, and communication capabilities. We propose to leverage smartphones to equip robots with extensive sensor suites, powerful computational abilities, state-of-the-art communication channels, and access to a thriving software ecosystem. We design a small electric vehicle that costs $50 and serves as a robot body for standard Android smartphones. We develop a software stack that allows smartphones to use this body for mobile operation and demonstrate that the system is sufficiently powerful to support advanced robotics workloads such as person following and real-time autonomous navigation in unstructured environments. Controlled experiments demonstrate that the presented approach is robust across different smartphones and robot bodies.